Enabling customers to bring critical technologies to market

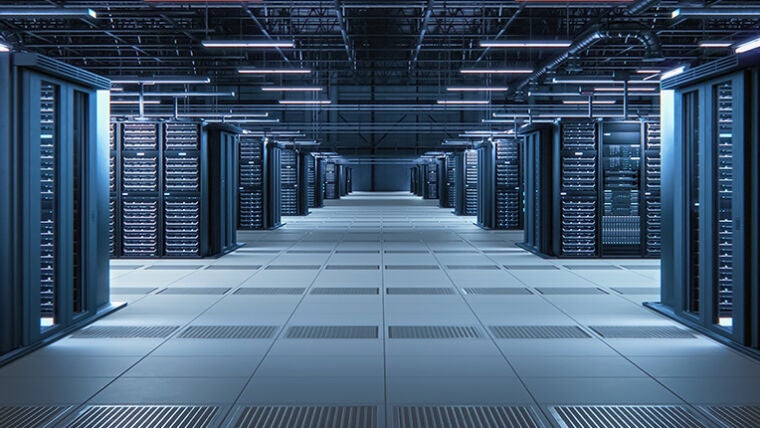

Unmatched reach across every major geography, powered by a world-class workforce that delivers precision at scale

140K+

Employees

100+

Facilities across ~30 countries

7K+

Supply chain professionals

16K+

Suppliers across global network

Tailored power solutions driving energy efficiency and performance while reducing operational costs.

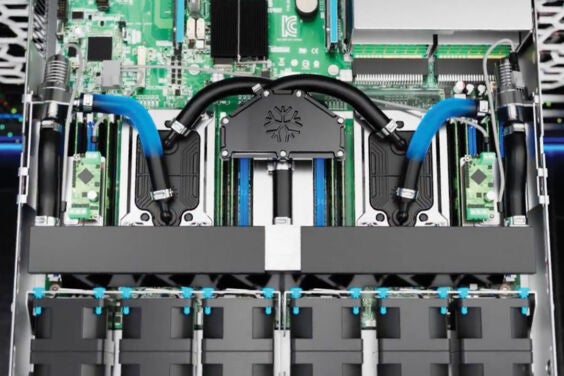

Addressing data center power density requirements by improving efficiency and reducing latency and space.

Board and rack level solutions to address the power density requirements and heat generated by AI data centers.

Design and engineering

Innovation capabilities and product enabling technologies to accelerate time-to-market and efficiencies

Supply chain

Global network, know-how, and technology to mitigate risk and complexity

Advanced manufacturing

Industry-leading advanced technologies to drive productivity, quality, and efficiency

Post production

Forward logistics and value-added fulfillment to configure products for market and channel needs and deliver seamless customer experiences

Post sale

Integrated reverse logistics and circular economy offerings to advance sustainable practices and maximize value recovery—at scale